How to Select Magnets for Magnetic Coupling?

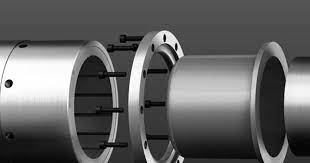

A magnetic coupling is comprised of two components: a driver and a follower. The driver is the portion of the mechanism that is connected to the prime mover (motor). Through magnetic interaction, the follower reacts to the motion of the driver, resulting in a non-contact transmission of mechanical energy.

This non-contact power transmission has multiple benefits:

• Isolation of components, which minimizes or eliminates mechanical vibrations through magnetic damping and allows for the insertion of a mechanical barrier between the driver and follower to separate environments and allow operation under pressure differentials.

• High tolerance of axial, radial, and angular misalignment between the prime mover and load.

• Allowance of speed variation and regulation between the prime mover and load.

To get the best air-gap magnetic field intensity for the same type and same size magnetic circuit, you should choose the most suitable magnetic materials for coupling. The permanent magnetic materials transferred torque must include the following properties:

1. High residual magnetic flux density to get the strong magnetic force and magnetic torque.

2. High coercivity (Br) to avoid demagnetized under high working temperature; that is to say, magnet needs a high magnetic energy product (BHmax).

3. Excellent temperature stability that material has the capacity to keep magnetic force stability.

Permanent magnet refers to the hard magnet with high coercive force, high remanence, which can keep constant magnetic force for the long term once magnetized. It can be divided into two types:

1. Metal alloy magnets: Nd2Fe14B, SmCo, and AlNiCo

2. Ferrite/Ceramic

NdFeB – Temperatures up to 150°C. Corrosion protection required.

SmCo – Temperatures up to 350°C. Corrosion protection is optional.

Ceramic – Temperatures up to 250°C. Corrosion protection not required.

Hysterlloy (hysteresis couplings) – Temperature is up to 350C. Corrosion protection not required.

All the above permanent magnets can be used on the magnetic coupling. But neodymium iron boron is the most widely used magnetic material due to high magnetic energy product (BHmax) and intrinsic coercive force. When under high working temperature (above 200 degrees Celsius), you can use the SmCo magnet which can reach 250 to 300 degrees Celsius.

From strong to weak magnetic force, magnets can be listed as below:

Sintered NdFeB > Sm2Co17 > Sm1Co5 > Bonded NdFeB > AlNiCo > Ferrite

Conclusion

Thank you for reading our article and we hope it can be helpful to you when it comes to how to select magnets for magnetic coupling. If you want to know more magnet products, we advise you to visit Deluge Power Magnets for more information.

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Daniel Wong

Phone: +86-18072358327

Tel: +86-18072358327

Email: info@delugepower.com

Add: YIWU County, Zhejiang Province, China