Waterproof Neodymium Bar Magnets with Epoxy Coating,

Neodymium magnets, block, epoxy-coated, used for speakers, sensors, earphones and servo motors

| Coating | Ni-Cu-Ni-epoxy |

| BHmax | 52MGOe |

| Grade | N42 |

| Shape | Bar,Block |

| Application | Linear actuators,Servo motors,Magnetic separators Microphone assemblies,DC motors,Computer rigid disc drives, printers and speakers,ect. |

1.What is the NdFeB Neodymium magnts?

NdFeB magnets are also know as Neo, Neodymium Iron Boron, NdBFe, NIB,

Super Strength, and Rare Earth Magnets (although SmCo also shares this term).

This data sheet covers the standard production 55. range of NdFeB magnets

(currently 55 grades) that are commonly in use. They are used in nearly all

Industries:- Automotive, Aerospace, Wind Turbine, Military, White Goods,

Lighting, Food Preparation, Separation, Motor and Generator Industries are

just a few example Industries. NdFeB magnets are all REACH and ROHS

compliant. NdFeB magnets can be made in blocks, discs, rings, arcs, spheres,

triangles, trapezoids and many other shapes

as stock and custom items. We manufacture NdFeB assemblies. We have a

NDA (Confidentiality Agreement) form if you require peace of mind relating

to confidentiality.

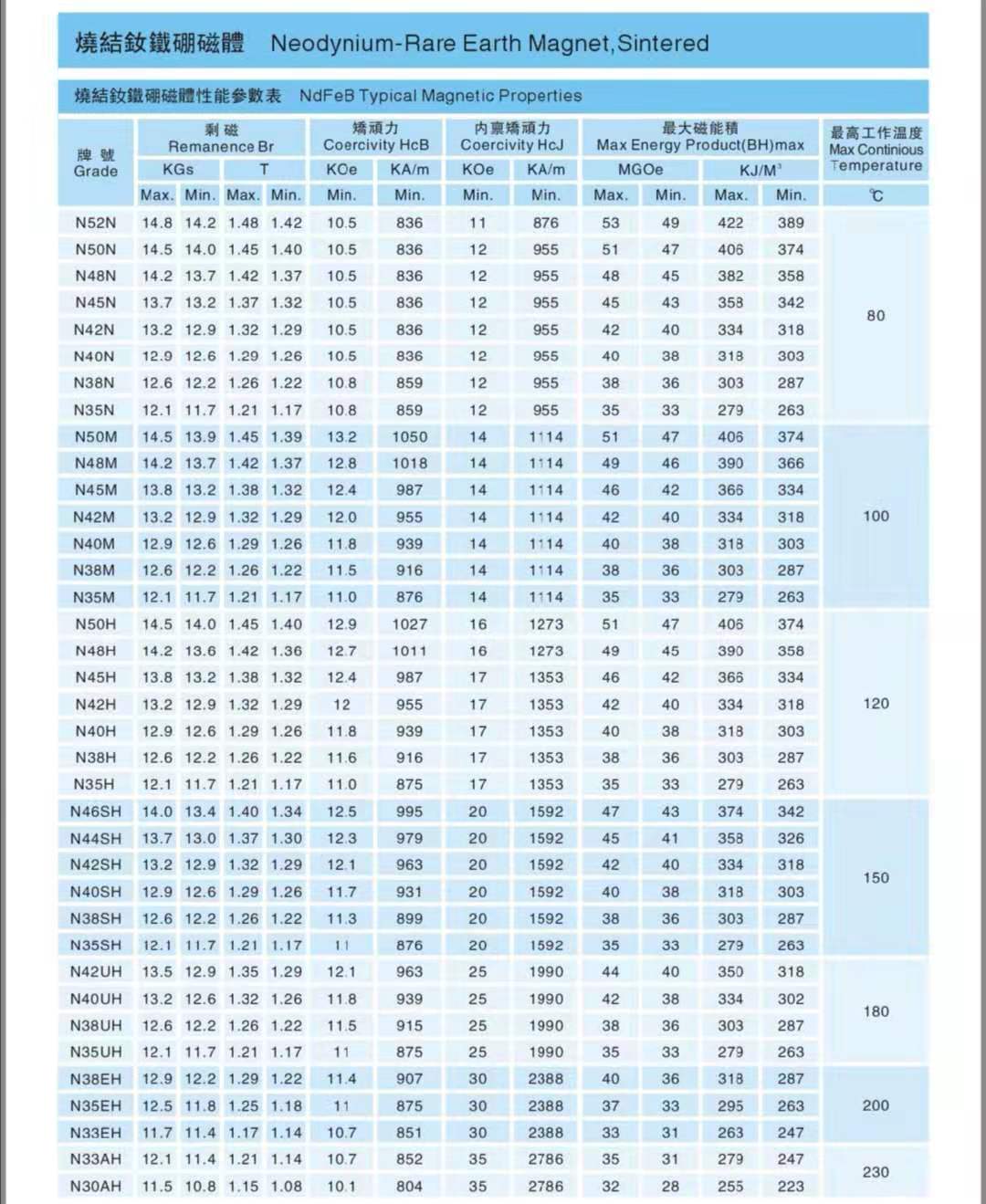

2.How many Grades we can provide?

The most common range of NdFeB (Nxx versions) will usually operate at up to

+80 degrees C. The temperature ratings are guideline values.

Higher temperature versions (NxxM, NxxH, NxxSH, NxxUH, NxxEH, NxxVH/AH)

are rated from up to +100 degrees C to a maximum of up to +230 degrees

C. The total magnetic circuit (magnet shape, other components, surrounding

environmental conditions) can impact on the actual maximum temperature

and performance. In some applications the temperature at which significant

weakening is seen may be at or slightly above the recommended maximum

temperature. In some applications the temperature at which significant

weakening is seen may be noticeably below the recommended maximum

temperature it depends on the application.

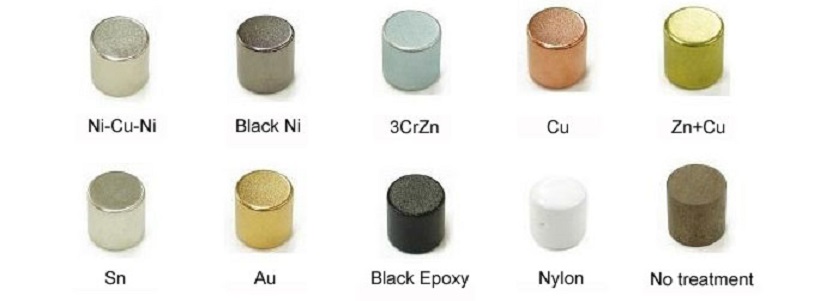

3.How to choose the coating for the Ndfeb magnet?

All NdFeB magnets should have some form of protective coating to minimise

and ideally prevent corrosion. Uncoated is not advised. The default / standard

protective coating is Ni−Cu−Ni plating. Other coatings/finishes exist (over

40 finishes are currently available). Where maximum corrosion resistance is

required for NdFeB, consider using the increased corrosion resistance range

of NdFeB alloys.

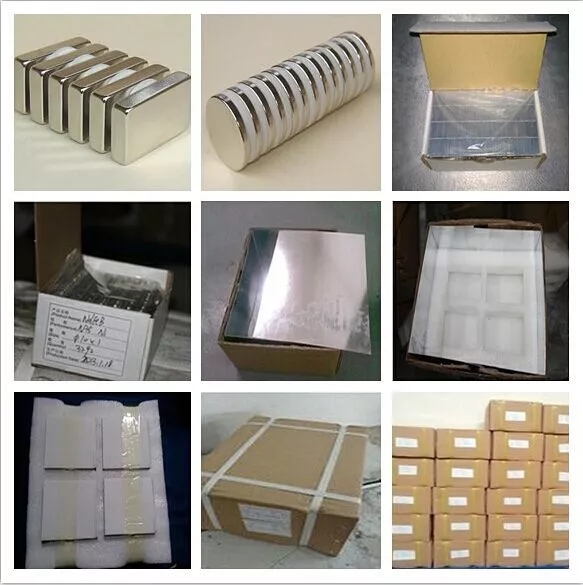

4.How We pack the NdFeb magnets?

For the Common shapes we do it as photo, but for customize ones, It depends.

5.How to Ship the Neodymium magnets?

We have our own account DHL and UPS.Every time just pay the magnetism testing

Fee for each Carton, It can be shpped smoothly. Meanwhile you can select ship your order

by sea or by train. No limit.

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Daniel Wong

Phone: +86-18072358327

Tel: +86-18072358327

Email: info@delugepower.com

Add: YIWU County, Zhejiang Province, China